Transforming EHS Performance and Driving Global Standardisation in Automotive Manufacturing

Managing EHS data across disparate geographies, legacy systems, spreadsheets, and paper processes.

A reactive approach to incident management hindered root cause analysis and the implementation of effective corrective actions.

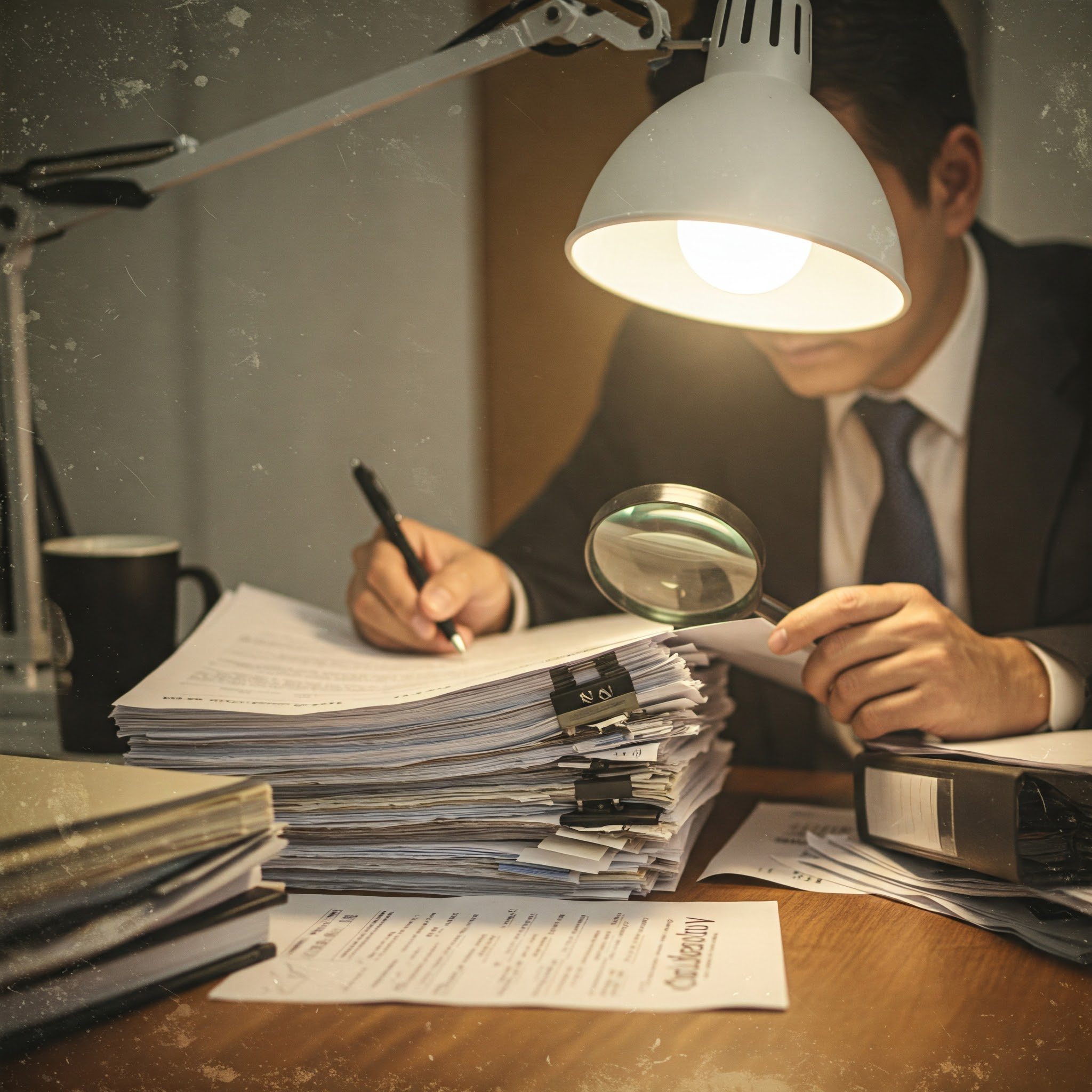

Manual audit and inspection processes were labour-intensive and error-prone, leading to audit fatigue and potential compliance gaps.

Inconsistent EHS practices and reporting across geographically dispersed facilities posed significant compliance risks.

Lack of clear visibility into leading and lagging EHS performance indicators hindered proactive risk management and improvement efforts.

Difficulty in cultivating a proactive safety culture and achieving meaningful employee engagement in EHS initiatives.

Staying current with rapidly changing global environmental regulations presented a significant and ongoing challenge.

Elevated insurance premiums due to a high incident rate impacted the company's bottom line.

To ensure a smooth and successful implementation, a multi-phased approach was adopted, prioritising high-risk facilities and processes. This phased rollout allowed for a controlled and iterative implementation, minimizing disruption and maximising the chances of success.

A dedicated cross-functional team, comprising EHS professionals, IT specialists, and plant managers, was assembled to oversee the implementation. This team provided the necessary expertise and coordination to ensure a seamless transition.

Recognising the importance of user adoption, extensive training and change management programs were conducted. These initiatives aimed to equip employees with the necessary knowledge and skills to effectively utilise the new system, while addressing any concerns or resistance to change.

To ensure a smooth integration with existing systems, careful planning was undertaken for data migration and system integration with ERP and HR systems. This step was crucial to avoid data inconsistencies and ensure a seamless flow of information across the organisation.

Finally, the system was configured to support both global standardisation of EHS processes and compliance with local regulatory requirements. This flexibility allowed the organisation to maintain a consistent approach while adapting to the specific needs of different locations.

A comprehensive EHS management system can drive significant improvements in safety performance, compliance, and operational efficiency.

Global standardisation of EHS processes is essential for multinational companies to ensure consistent safety practices and compliance.

A comprehensive EHS management system can drive significant improvements in safety performance, compliance, and operational efficiency.

Data-driven decision-making and continuous improvement are essential for maintaining a competitive edge in the manufacturing industry.

Careful planning, and a phased implementation, are essential for a successful EHS system deployment.

The system must be flexible, and able to adapt to changing regulations, and company needs.